Technology

High-quality, durable and energy-efficient solutions designed for unparalleled performance to stand the test of time.

An Intelligent Alternative

Reduce Costs / Minimize Risk: We combine proven steel construction methods with a Nationwide network of manufacturing locations and commercial steel contractors. EcoSteel uses a library of certified components that assemble with standard tools.

EcoSteel’s prefab construction process begins with 3D Engineering/Modeling and Shop Details. We then produce a pre-fabricated kit of parts that assembles on site. Our clients benefit by using Prefab technology and readily available materials and labor.

EcoSteel designs exclusively with pre-engineered steel building components. This allows us to deliver a superior platform of building information management (BIM) combined with the latest engineering and construction technology. Our clear-span curtain wall structure eliminates the need for load-bearing interior walls, freeing up space and enabling creative, cutting-edge designs.

Once Ecosteel and your Architect have agreed on a final design and framing layout, we finalize our structural drawings. We provide the the structural engineering stamp needed for permit along with a few high resolution exterior renderings to assist with city design approval. Our buildings are designed to meet or exceed local code while resisting earthquakes, hurricanes, floods, and wildfires.

“OUR VALUE ENGINEERING PROVIDES OPTIONS TO REDUCE BUILDINGS COSTS, LABOR AND CONSTRUCTION TIME”

Shell Features & Benefits

Superior Insulating Value

The advanced polyurethane core provides enhanced insulation values that significantly lowers heating and cooling costs across the entire wall area.

Eliminate Need For Trims

Optional folded corners and trimless ends eliminate need for trims on the Architectural wall panels.

One-Piece Construction

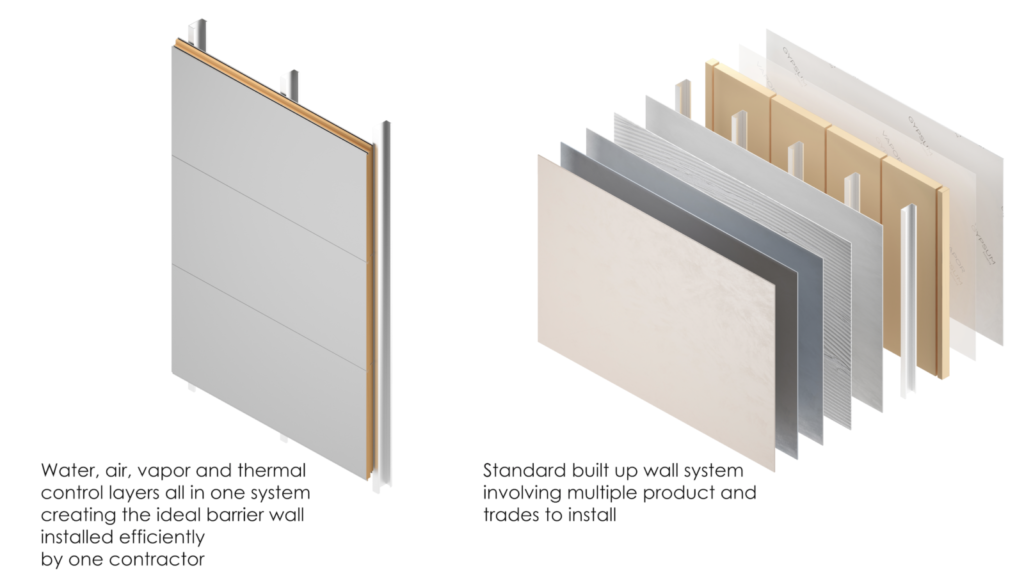

Factory fabricated composite panels are attached directly to the supporting structure and multiple steps to construct the insulated wall and roof are eliminated. Faster building completion means reduced construction and interim financing costs.

Impermeable Faces & Built-in Thermal Breaks

Ensuring the highest insulating values are maintained for the life of the building, panels are manufactured with impermeable faces and when installed the insulation is completely encapsulated by metal trim that creates an impermeable membrane on all sides of the panel. The aged “R” values are comparable to the initial “R” values many years after the buildings original completion.

Class 1 Polyurethane Foam

This type of foam meets the requirements of the major model building codes for many types of construction. Unlike panels with expanded polystyrene cores they will not produce a self-propagating fire. Local building codes may require automatic fire suppression systems for most installations.

Light and Strong

Panels are Lightweight, yet very strong and durable attributing to reduced costs for erection and structural support.

Creative Design

UNLIMITED DESIGN OPTIONS

Design flexibility is paramount in today’s custom driven market. Our steel frame can handle any shape, and our factory finished panels come in many different colors and styles.

Fixed Costs / Proven Methods

EcoSteel helps reduce costly mistakes in the construction process by utilizing BIM/ Parametric Engineering Technology. We also eliminate subcontractors which means less people to manage and fewer mistakes. Our Panelized / Prefab construction utilizes an easy to assemble building system.