5 Hidden Costs in Steel Building Projects (and How to Avoid Them)

Introduction

When you’re gearing up for a steel building project, it’s easy to get caught up in the big numbers—quick construction times, impressive durability, and that eye-catching price per square foot. Sure, steel structures come with genuine cost benefits, but there are often hidden expenses that first-time builders—and even seasoned pros—don’t anticipate. These can include site preparation, last-minute design changes, fluctuating material prices, or installation needs that weren’t factored in early on. That’s where EcoSteel makes a real difference. As a design-build partner committed to transparency and efficiency, we help our clients plan smart from day one—minimizing surprises through expert guidance, pre-construction planning, and integrated systems that simplify the build process. For business owners, developers, and contractors, overlooking these hidden costs can derail budgets and timelines. That’s why it’s critical to go beyond the sticker price of a building kit and consider the full scope of your project—from the foundation to long-term use. In this post, we’ll dive into five of the most common hidden costs in steel building projects—and more importantly, how partnering with EcoSteel helps you avoid them. Whether you’re constructing a warehouse, office, or retail space, being well-informed and well-supported is your best shield against costly surprises. A little planning now can lead to smoother construction, fewer change orders, and a more predictable route to completion.

Foundation and Site Preparation Expenses

One of the most commonly overlooked—and potentially expensive—aspects of a steel building project is the foundation and site preparation. It’s easy to focus on the excitement of the building kit itself, but without proper groundwork, construction can quickly stall and costs can spiral.

Before the first steel beam goes up, the site must be cleared, leveled, and possibly excavated. Soil testing is often required to ensure the ground can support the structure. If the soil proves unstable, you may need additional work like compaction or imported fill—unexpected steps that can drive up costs. On top of that, steel buildings require precisely engineered concrete foundations tailored to the structure’s layout, load demands, and soil conditions. These critical elements typically aren’t included in the basic building package and can vary greatly depending on the location and terrain. At EcoSteel, we understand how vital this early phase is. That’s why we work closely with clients from the start—often collaborating with local civil engineers to evaluate site conditions and plan for foundation requirements well before construction begins. We’re not just shipping a kit; we’re providing a comprehensive solution that helps you anticipate and mitigate these costs through informed, up-front planning. Skipping or underestimating this stage can result in costly delays or long-term structural challenges. With the right team and a solid site strategy, you can avoid these surprises and keep your project on track from the ground up.

Customization and Design Changes

When you receive an initial quote for a steel building, it often reflects a basic shell—a no-frills structure without the functional and aesthetic upgrades most clients ultimately need. As you begin tailoring the building to your specific requirements—larger windows, additional entryways, high-performance insulation, or architectural finishes—the price can escalate quickly. This is where many project owners hit an unexpected snag. It’s common to assume certain features are standard, only to discover later that they’re considered upgrades. Making design changes after the engineering phase begins can trigger costly delays, require re-engineering, or even necessitate new permits—all of which can throw your schedule and budget off course. At EcoSteel, we help clients avoid these mid-project surprises through our integrated design/build model. By working closely with you from the outset, we help define project goals early, clarify what’s included, and incorporate design features into the scope before any fabrication begins. This collaborative planning phase allows us to provide realistic, transparent budgeting—not just afterthought pricing—so you know exactly what you’re getting and what it will cost. Customization is often essential to meet operational, regulatory, or branding needs—but it doesn’t have to be a budget-buster. With EcoSteel, early design clarity leads to tighter cost control, fewer change orders, and a smoother path from concept to completion.

Material Price Fluctuations

Labor and Installation Oversights

It’s a common misconception that once your steel building kit arrives, the hardest part is over. In reality, one of the most frequently underestimated and potentially costly aspects of any project is labor and installation. While steel buildings are known for efficient assembly, getting them erected properly still requires experienced crews, specialized tools, and precise coordination. Installation involves far more than simply bolting panels together. You’ll need to handle crane operations, place anchor bolts accurately, verify structural alignment, manage weatherproofing, and often coordinate subcontractors for plumbing, electrical, and HVAC systems. If your crew isn’t familiar with steel construction—or worse, with your specific building system—errors can lead to expensive rework, structural risks, and project delays. At EcoSteel, we work proactively to help clients avoid these pitfalls. We recommend vetted contractors who have proven experience with our systems and provide comprehensive construction drawings that make the installation process clear and efficient. Our support doesn’t stop at design and delivery—we stay involved to help ensure your project goes up as smoothly as it was planned. Don’t let labor become an afterthought. Budget carefully for qualified steel building installers, and make sure they understand the scope and sequence of the work. With the right team and guidance from EcoSteel, you can prevent costly missteps and keep your project on track from day one.

Long-term Maintenance and Energy Efficiency

When budgeting for a steel building, it’s easy to focus on the upfront price and overlook the long-term costs that come after construction. But maintenance and energy efficiency are critical factors that directly impact the total cost of ownership—and the value of your investment over time. While steel buildings are celebrated for their durability, they’re not entirely maintenance-free. Over the years, costs can arise from roof sealant touch-ups, HVAC servicing, and occasional repainting. The real hidden cost, however, often lies in poor energy performance. If you cut corners on insulation or opt for low-efficiency systems, you could face rising utility bills and discomfort—especially in regions with extreme climate swings. EcoSteel helps clients sidestep these long-term pitfalls by integrating energy performance into the core of our design process. Our buildings feature insulated metal panels, high-performance coatings, and advanced system detailing to reduce thermal bridging and improve overall building envelope performance. Many of our structures not only meet but exceed current energy code requirements and often qualify for green building incentives or tax credits.

By designing for longevity and efficiency from day one, EcoSteel enables you to reduce operational costs, minimize maintenance demands, and maximize return on investment. Energy efficiency isn’t just an upgrade—it’s built into the way we do business, ensuring that your building performs as beautifully in year twenty as it did on day one.

LEARN MORE – ADDITIONAL RESOURCES

Read more on: How to Maximize Value and Avoid Hidden Costs with Prefabricated Metal Buildings

Conclusion

Steel buildings offer unmatched strength, speed, and cost-efficiency—but only when planned and executed with care. While hidden costs like site prep, mid-project design changes, labor oversights, and long-term energy inefficiencies can catch many builders off guard, they don’t have to derail your project. That’s where EcoSteel makes a real difference. Our hands-on, design/build approach ensures clients understand the full scope of their project from day one. From early-stage planning and custom engineering to recommending experienced contractors and integrating high-performance materials, we help eliminate costly surprises before they surface.

By partnering with EcoSteel, you’re not just buying a building kit—you’re gaining a dedicated team committed to transparency, precision, and long-term value. The result? A smoother construction process, fewer change orders, and a building that delivers superior performance for decades to come. Hidden costs don’t stand a chance when you have the right partner. With EcoSteel, you’ll have confidence in your budget, clarity in your design, and a steel building that exceeds expectations.

WHY ECOSTEEL?

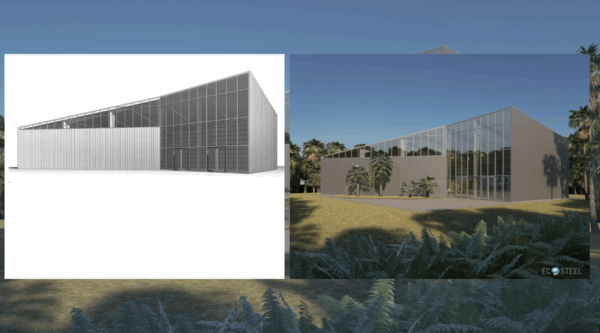

EcoSteel building systems come in a variety of shapes and sizes, but at their core they all utilize a custom engineered structural steel frame and a high-performance insulated shell. From sub-zero temperatures to dry heat or high humidity, Mother Nature continually tests the limits of building envelopes. While our insulated wall panels are a popular option, sometimes they are substituted or combined with masonry, stone, pre-cast or tilt-up concrete, wood, glass or other architectural wall treatments. The versatility and flexibility of our building systems allows for a myriad of colors, shapes, textures and designs. Today’s building projects require the perfect combination of energy efficiency, creative versatility, and reduced construction cost.

You must be logged in to post a comment.