Step-by-Step Guide to Custom Metal Building Design

Custom metal buildings have transformed modern construction by delivering durability, energy efficiency, and design flexibility for nearly every application. Whether for commercial, industrial, or residential use, metal structures offer a cost-effective alternative to wood or concrete, with faster construction times and lower long-term maintenance. From warehouses and retail centers to prefab homes and storage units, demand continues to grow thanks to their long lifespan and performance.

Designing a custom metal building gives property owners complete control over layout, aesthetics, insulation, and sustainability features. However, it requires careful planning, and an understanding of material options and building codes. Many people ask, “Can I design my own metal building?” or “What is the cost of a 1,000 sq. ft. metal structure?”—questions that highlight the need for proper guidance.

Moreover, this guide explains the step-by-step process of planning and constructing custom metal buildings, helping you turn your blueprint into a functional, modern structure.

Defining Your Building Needs and Purpose

The first step in designing a custom metal building is defining its purpose. Whether you need a commercial warehouse, retail space, agricultural barn, or residential metal home, the intended use determines the size, layout, and key features of the structure.

Begin by asking essential questions:

How will you use the building?

What size and dimensions best suit your needs? What dimensions fit your needs—such as a 1,000 sq. ft. space for a small business or a 30×40 workshop with a concrete slab?

What features matter most, including insulation, ventilation, or roll-up doors?

Will you need space for future expansion?

Once these requirements are clear, you can estimate costs more accurately. Metal buildings cost-effective compared to traditional construction. Pricing varies based on customization. Materials and location also influence the total cost. Clear planning ensures long-term functionality and value.

Designing Your Custom Metal Building

Designing your custom metal building is the stage where your vision becomes tangible. Moreover, this phase focuses on functionality, compliance, and long-term performance.

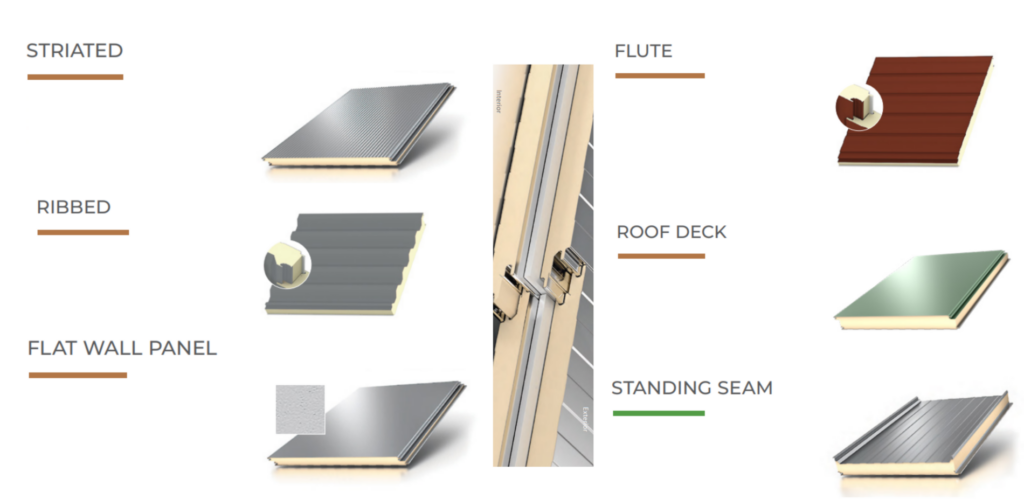

You’ll work with design professionals to define structural dimensions, roof styles, and wall panels. They will also help determine door and window placements, along with interior layouts. Climate, intended use, and future expansion should also guide your decisions.

Modern tools like Building Information Modeling (BIM) provide accurate 3D renderings, improving coordination between engineers, architects, and fabricators while reducing errors and delays. Sustainable options, such as insulated panels and passive design features, can added to enhance efficiency.

Thoughtful customization ensures your metal building meets today’s needs while remaining adaptable for future growth.

Collaborating on Custom Design and Engineering

Custom metal buildings rely on thoughtful planning and close collaboration with architects and engineers. In addition ,this stage shapes your vision into detailed designs for offices, warehouses, or mixed-use structures, ensuring every element—from layout to structural needs—is intentional and aligned with project goals.

Designers help you select roof styles, panels, insulation, and energy-efficient features, while engineers evaluate site conditions, environmental loads, and code requirements for safety and durability. The result is precise blueprints and 3D models that clarify the final structure before fabrication.

This collaborative process enhances functionality and streamlines prefabrication and construction, turning ideas into engineered solutions.

Prefabrication and Delivery Process

Once your metal building design is finalized, the prefabrication process begins. This stage is crucial as it ensures precision, quality control, and faster assembly. Prefabrication involves manufacturing the building components—such as steel frames, wall panels, and roofing systems—at an off-site facility before they transported to your construction site.

1. Manufacturing and Quality Control

During the manufacturing phase, advanced computer-aided design (CAD) and CNC machining technologies used to ensure each component is accurately cut, welded, and formed. This reduces the need for on-site adjustments, saving time and reducing labor costs. The factory environment also allows for strict quality control, ensuring that all components meet high standards before they leave the factory.

2. Customization and Coating

If you’ve opted for custom features, such as insulated metal panels (IMPs), skylights, or fire-resistant coatings. These added during the prefabrication stage. Many manufacturers also apply protective coatings at this time. Galvanized finishes help improve durability and increase resistance to weather conditions.

3. Shipping and Site Preparation

Once fabrication is complete, the building kit is carefully packaged and shipped to your site. Shipping costs depend on location and the complexity of the delivery. To ensure a smooth installation, it’s crucial to have the site properly prepared, including a ready foundation and storage space for the prefabricated components.

Assembly and Construction

The assembly and construction phase is where your metal building design starts to take shape. Once the prefabricated components have arrived at the construction site, the process moves to the next stage: assembly. This phase is typically faster than traditional construction due to the precise prefabrication of parts.

1. Foundation and Site Preparation

Before assembly begins, it’s crucial to ensure that the foundation is properly laid. Furthermore, a concrete slab or pier foundation is often used for metal buildings, depending on the structure’s size and intended use. Site preparation also includes ensuring that the area is cleared of debris and level, as this directly affects the stability and alignment of the structure.

2. Steel Frame Installation

The first step in assembly is the installation of the steel frame. Moreover, this includes erecting vertical columns, horizontal beams, and braces that form the skeleton of the building. Steel frame buildings known for their durability and strength, providing a solid foundation for all other components.

3. Paneling, Roofing, and Final Touches

Once the frame is set up, the next step involves attaching the roofing panels and wall systems, followed by any insulation or custom features. Depending on the design, you may also add windows, doors, and exterior cladding.

Throughout this phase, construction crews ensure that all components securely fastened and meet safety standards. The assembly process typically takes a fraction of the time compared to traditional building methods, making prefabricated metal buildings a highly efficient construction solution.

Final Touches and Inspections

The final touches and inspections phase is critical to ensuring that your custom metal building is not only functional but also meets all regulatory requirements. Once the structure is assembled, the next steps involve completing the interior and exterior finishes, followed by thorough inspections to guarantee safety and quality.

Interior and Exterior Finishes

This stage involves adding the finishing touches to both the interior and exterior of the building. For the exterior, this might include painting, cladding, or installing trim for aesthetic appeal and weather protection. On the interior, tasks like installing insulation, electrical wiring, HVAC systems, and lighting fixtures carried out, ensuring the building is fully operational. Depending on the intended use, custom features such as partition walls, flooring, or specialized equipment might also added.

Safety Inspections

Before the building can used, it must undergo inspectionsto ensure it complies with local building codes, zoning regulations, and safety standards. These inspections can include structural integrity checks, electrical system evaluations, and fire safety assessments. HVAC functionality tests may also required.

3. Final Approval

The final touches and inspections phase ensures your metal building is complete, safe, and ready to serve its intended purpose for years to come.

Conclusion

Designing and constructing a custom metal building requires a clear, systematic approach to ensure your vision becomes a durable, efficient, and high-performing structure. From defining your needs and selecting the right design to understanding costs, prefabrication, and assembly, every stage contributes to long-term functionality and value. Once the final touches and inspections are complete, your building is safe, compliant, and ready for use—giving you confidence that your investment is protected.

Choosing quality materials and the right construction partner is essential to achieving the best results. At EcoSteel, we specialize in custom metal building design and deliver tailored solutions built for strength, efficiency, and longevity. Additionally, our team ensures your project stays on schedule, on budget, and aligned with the highest standards.

If you’re ready to turn your blueprint into a modern, resilient structure, contact EcoSteel today for expert guidance and innovative building solutions.

WHY ECOSTEEL?

EcoSteel building systems come in a variety of shapes and sizes, but at their core they all utilize a custom engineered structural steel frame and a high-performance insulated shell. From sub-zero temperatures to dry heat or high humidity, Mother Nature continually tests the limits of building envelopes. While our insulated wall panels are a popular option, sometimes they are substituted or combined with masonry, stone, pre-cast or tilt-up concrete, wood, glass or other architectural wall treatments. The versatility and flexibility of our building systems allows for a myriad of colors, shapes, textures and designs. Today’s building projects require the perfect combination of energy efficiency, creative versatility, and reduced construction cost.