EcoSteel designs and supplies new industrial chic buildings that are visually appealing, durable, and fire resistant. Our prefab buildings are designed and assembled much faster than traditional methods. Check out a few of our recent breweries below!

DISCRETION BREWERY – Santa Cruz, CA

The original Homespace+Workspace retail store burned down in. This client came to EcoSteel seeking to build with fire resistant materials, but also sought a visually pleasing retail space be achieved using EcoSteel’s commercial and industrial methods and materials. The result is a 10,340 square foot steel building complete with 2HR fire rated panels. To ensure this project remains on budget, interior structural elements were left exposed. The back interior faces of our pre-insulated steel panels were also left exposed to shave cost and provide a unique and interesting interior look. EcoSteel will overlay this project’s MEP plans with our BIM 3D modeling to ensure elegant integration. This client also chose EcoSteel because of our Revit 3D modeling capabilities. It was important to easily make design changes early in the process in a virtual environment to ensure the client’s design desires were met.

Click Here View The Full Discretion Brewery Gallery

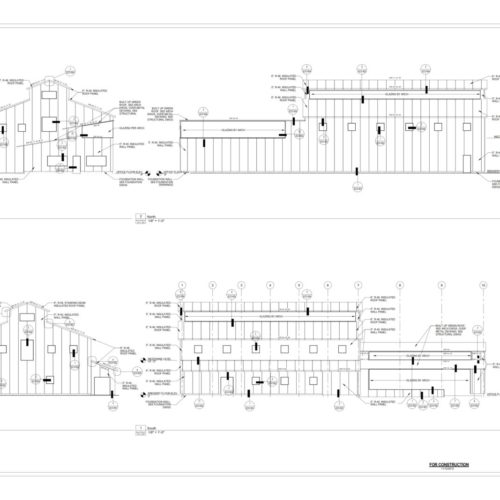

Catskill Brewery – New York

New EcoSteel Prefab project in New York, with custom trusses and clerestory windows. This all steel bolted frame construction is Approx 12,000SF. The building will incorporate a planted roof section, insulated wall and roof panels provide unmatched energy efficiency. Fire resistant steel frame and Fire Rated panels provide superior strength and resilience with combustible building operations.

Our Process:

Design + Engineering

EcoSteel designs exclusively with pre-engineered steel building components. This allows us to deliver a superior platform of building information management (BIM) combined with the latest engineering and construction technology. Our pre-engineered steel modeling technology accelerates the creation of 3D design, along with construction plans, fabrication drawings, and files needed for production.

Once we have a final design we will then value engineer the design by creating a 3D prefabricated steel structural framing plan with a detailed roof and wall panel layout. This allows us to resolve any potential construction conflicts prior to steel assembly. We provide a majority of the drawings needed for permit, no matter the code. Intense seismic code? Yawn. Hurricane, flood, wildfire, pest danger imminent? No problem.

Fabrication + Assembly:

Once you have received your permit, EcoSteel is then kicked into production mode. We develop shop and fabrication drawings which allow your custom design to be converted into a kit of parts to be bolted together on your jobsite.

No specialized labor needed. We produce detailed erection drawings so any certified steel erection crew in any part of the country will be able to cheaply, efficiently and quickly assemble your project. This prefab approach to custom design allows for dramatically faster build times, which saves you time, money and minimizes your risk. Once we have engineering completed EcoSteel will reach out to partner steel erectors as well.

Build Out and Move In!

Our clients love to express the strength and beauty of steel while reducing costs and construction time. You will find concrete floors that are stained instead of wood flooring, and there are typically exposed steel elements throughout the interior and exterior of the home depending on the building components used. The idea is to eliminate finish carpentry and cosmetic materials wherever possible while maintaining an clean industrial chic look!

You must be logged in to post a comment.