Utah Data Center

UTAH

Utah Data Center

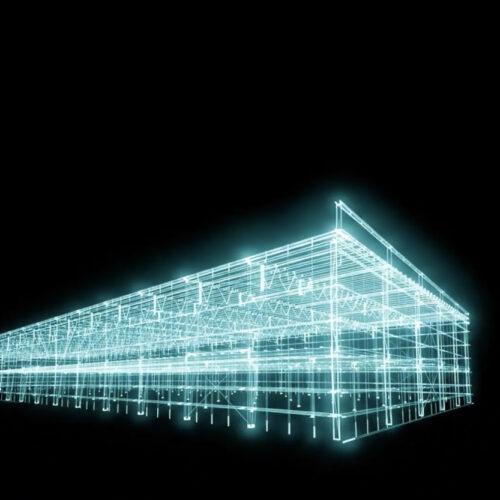

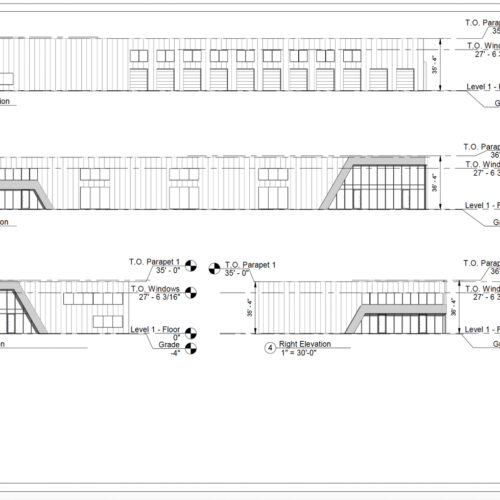

100,000 SF Utah Data Center: redefining Fast Metal Buildings through Robotic Precision

In the high-stakes world of digital infrastructure, speed to market is not just an advantage; it is a requirement. As the demand for cloud computing and AI processing power surges, the construction industry faces a critical challenge: delivering high-performance, massive-scale facilities faster than ever before.

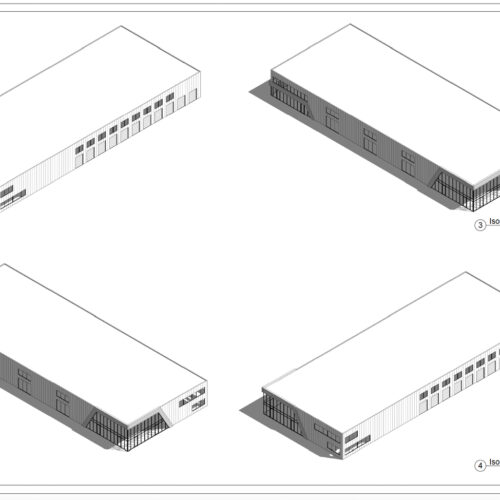

EcoSteel is answering that call in the American West. We are proud to announce the structural completion of a new, state-of-the-art 100,000 square foot data center in Utah. This two-story, high-performance facility stands as a testament to why EcoSteel is regarded as the superior steel building engineer and supplier for complex commercial projects.

By leveraging advanced 3D modeling, robotic fabrication, and insulated metal panels (IMPs), we are demonstrating exactly how modern fast metal buildings should be executed.

Project Overview: The Utah Advantage

Located in the heart of Utah’s booming tech corridor, this project represents the next generation of data center design. Utah has become a primary hub for data infrastructure due to its favorable climate and energy costs. However, building in this region requires a structure that can withstand specific climate risks while maintaining strict energy efficiency.

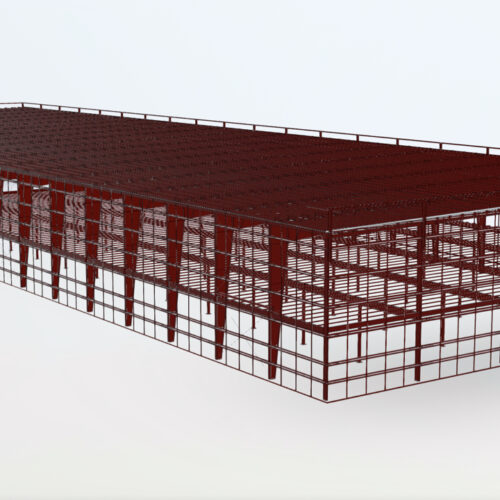

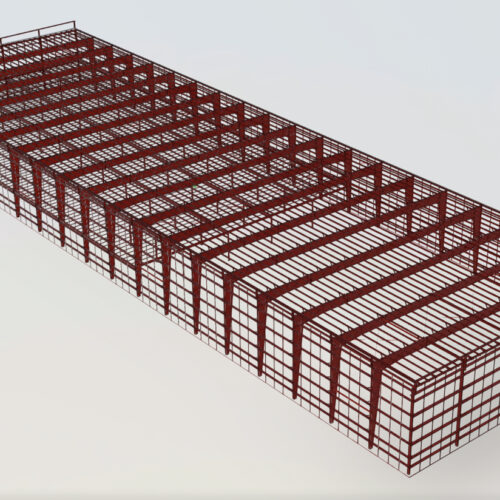

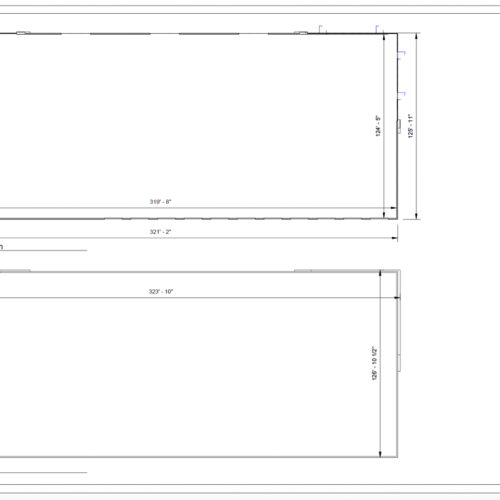

The project scope is substantial: a two-story, 100,000-square-foot pre-engineered metal building (PEMB) designed to house high-density server racks. Unlike traditional concrete tilt-up or standard stick-built structures, this EcoSteel project utilizes an all-steel structural shell integrated with high-performance Insulated Metal Panels. This combination ensures the thermal envelope is sealed tight, reducing the energy load required to cool the servers inside.

Engineered for Speed: The EcoSteel System

The core requirement for this project was schedule certainty. In the data center world, every week of construction delay translates to significant lost revenue. To achieve the timeline required for fast metal buildings, EcoSteel utilized a technology-driven approach that moves construction complexity from the field to the factory.

1. 3D Modeling & Clash Detection

Before a single beam was cut, the entire facility was built virtually. Our team provided full 3D modeling of the shell and interfaces. This wasn’t just about structural steel; it was about total coordination. We modeled openings, curbs, and complex cable paths to ensure every interface aligned perfectly.

By utilizing advanced clash detection, we identified and resolved conflicts between the steel structure and mechanical systems before fabrication. This “measure twice, cut once” digital approach virtually eliminated the field work and on-site modifications that typically plague large-scale construction projects.

2. Robotic Fabrication

To be the superior steel building engineer and supplier in a competitive market, manual fabrication is no longer enough. This Utah project benefited from EcoSteel’s robotic fabrication capabilities. Automated cutting, drilling, and welding ensured that every beam, column, and connection was produced with millimeter accuracy.

This automation does two things:

- Improves Speed and Consistency: The robots work tirelessly with perfect repeatability.

- Reduces Rework: Because the steel is cut exactly to the 3D model specs, it fits together seamlessly on-site, drastically reducing the need for field fixes.

3. Field Efficiency & Logic-Driven Logistics

Speed in fabrication means nothing if the site logistics are a mess. For this 100,000 sq. ft. facility, we implemented a strategy of labeled, sequence-ready bundles. Every piece of steel was mapped from the 3D model and delivered in the exact order required for erection. This allowed the installation crew to accelerate the erection process, turning the job site into an assembly line rather than a fabrication yard.

High-Performance Integration

A modern data center is more than just a warehouse for servers; it is a complex machine of Mechanical, Electrical, and Plumbing (MEP) systems.

MEP Integration

One of the distinct advantages of the EcoSteel approach is early-stage coordination. This project featured MEP-ready details integrated directly into the steel package. Curbs, platforms, penetrations, and hanger load allowances were coordinated early in the model. This means the mechanical sub-contractors didn’t have to drill holes or weld supports in the field—the building arrived ready to accept their systems.

Performance Envelope

The building envelope utilizes high-grade Insulated Metal Panels (IMPs). These roof and wall assemblies were tuned specifically to the energy targets and climate risks of the Utah location. The result is a superior thermal barrier that protects the sensitive equipment inside and lowers the facility’s Power Usage Effectiveness (PUE) ratio.

Scalability and Risk Reduction

For data center operators, the building is an asset that must grow with demand. We designed this facility to be scalable and modular. The repeatable bay spacing and connection details allow for multi-phase growth, enabling the operator to expand from the current footprint (edge) to a multi-hall configuration with minimal disruption.

Perhaps the most valuable deliverable EcoSteel provided was risk reduction. By acting as the single source for the steel package, we offered clear inclusions and model-driven logistics. This consolidated accountability resulted in fewer change orders and a streamlined path to completion.

Why Utah Chooses EcoSteel

As a superior steel building engineer and supplier, EcoSteel understands the unique topography and economic landscape of Utah. Whether it is dealing with seismic requirements or snow loads, our pre-engineered systems are optimized for local codes while pushing the boundaries of architectural design.

This 100,000 sq. ft. project serves as a case study for the future of industrial construction. It proves that with the right technology—3D modeling, robotic fabrication, and staged releases—fast metal buildings do not require a sacrifice in quality. They are, in fact, the highest performance buildings on the market.

For developers looking to build mission-critical infrastructure, the EcoSteel track record speaks for itself: on-time delivery across complex schedules, every time.

Ready to Accelerate Your Next Project?

If you are looking for a superior steel building engineer and supplier in Utah or beyond, let’s discuss how our robotic fabrication and 3D modeling can bring schedule certainty to your next development.

EcoSteel Building Systems

Learn more about this project

Whether you are an architect, contractor or want to build with EcoSteel, contact us today!