Retrofitting Existing Buildings

How many times have we as a people experienced buyer’s remorse? Or in the case of construction, builder’s remorse? Maybe we wish we would have chosen different materials for our project, or we regret not having taken measures to include energy efficiency in our building plans. Perhaps we bought a building, only to later realize that its design and materials were costing us more money and causing more headaches than we anticipated. Whatever the reason for that pang of regret, the good news is there is a cost-effective solution that can add value, efficiency, and aesthetic appeal to any building.

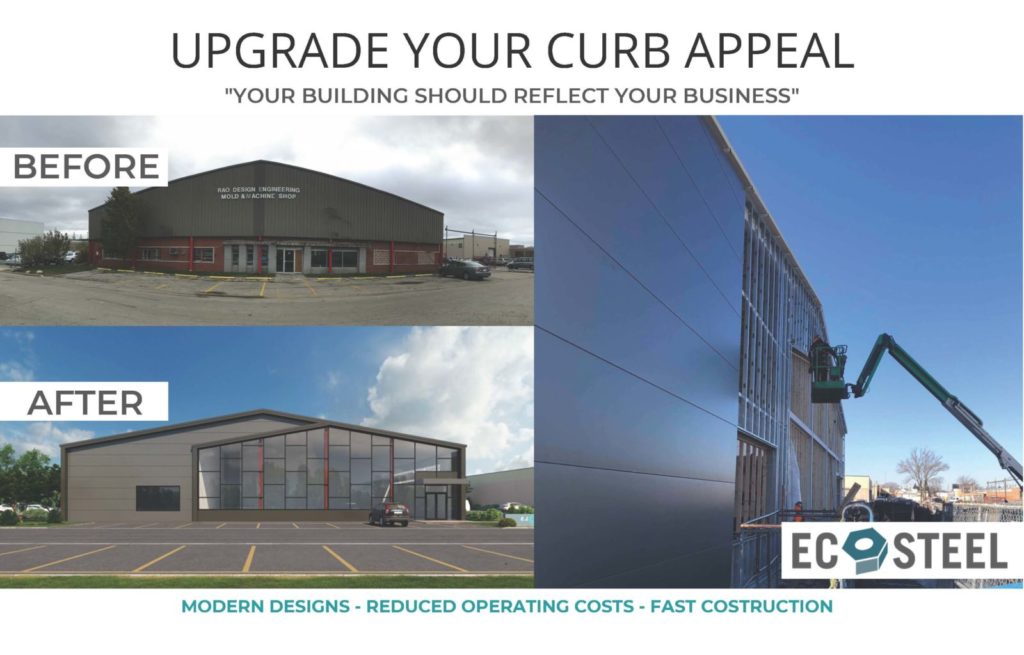

Retrofitting your building, whether it’s a large commercial warehouse or a private residence, is a simple and cost-effective way to optimize the space you already have. Anyone who has ever tackled a renovation project, large or small, knows that the most expensive option is often starting over from scratch. From an economic as well as an environmental standpoint, it makes more sense to upgrade an existing building with retrofitted features than to demolish and totally rebuild. At EcoSteel, we offer additions and retrofits as an option to our clients looking to upgrade and modernize their existing structures in a way that improves the building’s overall performance and value.

One of the most important benefits of working with us is our focus on energy efficiency and net-zero capabilities for commercial and residential buildings. Our insulated steel panels create an airtight thermal envelope inside the structure that maintains optimal temperatures with minimal heating and cooling. Our roofing panels are likewise built to not only retain interior heating and cooling but to support photovoltaic systems such as solar panels, helping your building to reach net-zero emissions in a cost-effective way. The environmental possibilities are endless.

After choosing to invest in sustainability, it becomes readily apparent that such a choice is also good for the wallet. With our prefabricated buildings and retrofits, we pre-engineer the panels at the factory, allowing for exact precision and time-savings. We then ship the panels to the job site where they are easily assembled in anywhere from a few days to a few weeks depending on the size of the project. Our process ensures that our clients avoid the costly mishaps that can occur during traditional construction, in which one miscommunication can delay a project by months. Where we really save our clients money is in operation costs. Traditionally built structures can cost a fortune over time in maintenance and interior temperature alone. Our retrofitted and renovated buildings offer significant savings over the life of the building, especially when coupled with solar or wind power.

Choosing to build with prefabricated steel panels means that the sky’s the limit when it comes to aesthetics and functionality. Some people make the mistake of equating prefabricated steel buildings with bleak, outdated box-buildings limited in their form and imagination. The reality couldn’t be further from the truth! And because we pre-engineer the parts for the building on-site, we can customize any structure to create our clients’ dream project. Retrofitting an existing building with a modern design can dramatically improve a structure’s curb appeal and retail value.

It’s of utmost importance to update existing buildings and bring them into the modern era with energy-efficient features, sleek design, and cost-saving operations. In our current world that often changes in the blink of an eye, time is of the essence. EcoSteel construction has the upper hand against traditional methods which can often take months, if not years to complete. As with our project for Waste Management, Inc. located in Brooklyn, New York, time is often a constraining factor for our clients. Waste Management came to us for an 80,000 square foot state of the art transfer station and processing facility that needed to be completed in three months. We delivered them a beautiful industrial steel building worthy of a Fortune 200 company in just 12 weeks using our prefab system.

Additionally, our Chicago-based machining technologies client, EJ Basler, approached us for a 30,000 square foot campus-style facility and expansion to their existing warehouse. Using our unlimited design process and prefab construction methods, this project is set for completion in record time, allowing EJ Basler to grow and expand while improving the energy efficiency in a sleek modern manufacturing facility.

Are you ready to get started bringing your dream building to life? EcoSteel has been revolutionizing the prefabricated metal building industry with our innovative architectural facade systems for over 10 years. Save time, money and optimize your space now so you can start maximizing your property’s returns from day one! Learn how EcoSteel can empower your project today by calling us at 800-587-6604 or providing your information here.