The Critical Role of Structural 3D Modeling in Modern Construction

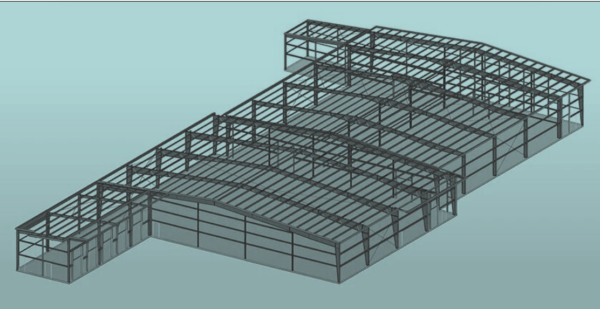

The construction industry is rapidly evolving, with technological advancements transforming how buildings are designed, fabricated, and constructed. Structural 3D modeling has emerged as a pivotal innovation in this landscape, offering unmatched precision and collaboration. At EcoSteel, we leverage the power of 3D modeling software like Tekla and Revit to deliver innovative steel building solutions for commercial, residential, and industrial projects.

This article explores the transformative benefits of structural 3D modeling and how it helps EcoSteel achieve superior results in project delivery and sustainability.

Understanding Structural 3D Modeling

Structural 3D modeling involves creating detailed, data-rich digital representations of building structures. This process offers a significant advantage over traditional 2D drawings by providing a more comprehensive and accurate view of the project’s structural elements. Unlike 2D plans, which can be prone to misinterpretation, 3D models offer clarity in design, highlighting every aspect of the structure, including load paths, material specifications, and connection details.

At EcoSteel, we use Tekla and Revit to develop precise, information-rich models that integrate every element of our steel buildings. This holistic approach helps streamline the workflow from design to fabrication, ensuring that every phase of construction runs smoothly.

The Advantages of Structural 3D Modeling

1. Design Precision and Accuracy

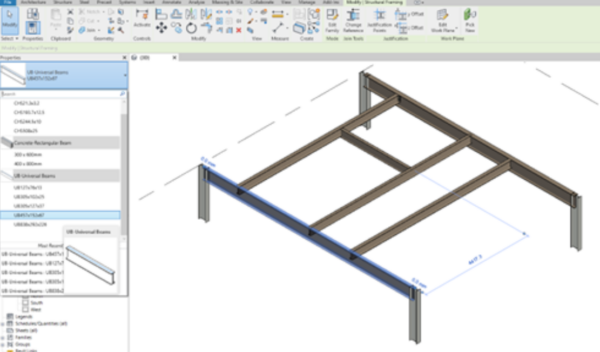

In construction, precision is paramount. Any error in design can lead to costly delays, structural issues, or even project failure. Tekla and Revit enable us to create highly detailed models that reduce design errors, ensuring that each building component fits perfectly. Tekla, known for its steel detailing capabilities, allows for the creation of detailed steel structures, including connection types, welds, and fabrication-ready components. Revit, on the other hand, provides a broader Building Information Modeling (BIM) platform that integrates architectural, structural, and MEP systems into a single model.

This ensures that when the fabrication stage begins, all components are accounted for, reducing the likelihood of on-site adjustments and ensuring seamless assembly.

2. Enhanced Team Collaboration

Construction projects involve multiple teams, including architects, engineers, contractors, and fabricators. Miscommunication between these parties can lead to delays and errors. With structural 3D modeling, collaboration is significantly improved.

Revit’s cloud-based collaboration tools enable all project stakeholders to work on the same model in real time, ensuring that everyone is working with the latest design iteration. This allows teams to coordinate their efforts effectively, improving communication and reducing potential misalignments between structural elements, MEP systems, and architectural designs. At EcoSteel, this integrated approach has been critical in delivering complex projects with precision. It enables a coordinated, transparent workflow that ensures on-time delivery without compromising on quality.

3. Early Clash Detection

In any construction project, conflicts between different building systems—such as structural elements and MEP components—can lead to costly delays and rework if not identified early. Structural 3D modeling offers the ability to detect clashes before construction begins, avoiding costly mistakes and ensuring smooth project execution. Both Tekla and Revit offer powerful clash detection tools, enabling engineers and designers to address conflicts between steel framing and MEP systems before they become problems on-site. By identifying and resolving these issues early in the design process, we minimize the risk of rework and ensure that the final build proceeds without unexpected interruptions.

4. Improved Client Communication and Visualization

Communicating the complexities of a design to clients can be a challenge, especially when relying on traditional 2D drawings. Structural 3D modeling offers a powerful solution by providing clients with detailed visual representations of the building. Clients can view the structure from various angles, explore different design options, and even experience virtual walkthroughs, allowing them to fully understand the final product.

At EcoSteel, we use Tekla and Revit to create highly detailed 3D models for client presentations. This helps our clients better visualize the project and provides a platform for informed decision-making. It also ensures that our designs align with their expectations from the start, preventing costly changes down the line.

5. Cost Efficiency and Material Optimization

Cost overruns are a significant concern in the construction industry, often caused by inefficient material use, errors in fabrication, or rework. Structural 3D modeling helps optimize material use and minimize waste by providing accurate material quantities and dimensions. With Tekla’s detailed steel models and Revit’s integrated system models, we can ensure that the correct amount of materials is ordered, eliminating the risk of over-ordering or material shortages. This results in reduced project costs and a more sustainable building process, aligning with EcoSteel’s commitment to environmental responsibility.

6. Sustainable and Environmentally Friendly Construction

Sustainability is a core value at EcoSteel, and structural 3D modeling plays a critical role in our ability to deliver environmentally responsible projects. By optimizing material use and minimizing waste, we reduce the carbon footprint of our projects. In addition, by using prefabricated steel components, we further contribute to sustainability by reducing on-site waste and lowering the energy needed for assembly. Our use of Tekla and Revit also allows us to explore sustainable design options more easily. From energy-efficient layouts to material-saving structural solutions, our 3D models give us the insights needed to design buildings that are not only structurally sound but also environmentally responsible.

How EcoSteel Uses Tekla and Revit

At EcoSteel, we specialize in prefabricated steel buildings that are custom-designed to meet the specific needs of our clients. Our expertise spans across commercial, residential, and industrial projects, where precision, durability, and sustainability are paramount. By integrating Tekla and Revit into our workflow, we ensure that every steel building we design meets the highest standards of structural integrity and performance. From initial concept design through to fabrication and installation, these software platforms provide the level of detail and collaboration needed to deliver world-class steel structures efficiently.

Tekla for Steel Detailing

Tekla is our go-to software for steel detailing, allowing us to create precise, fabrication-ready models. The platform’s detailing capabilities are unmatched, offering granular control over connection details, welds, and material specifications. By generating accurate shop drawings directly from the 3D model, Tekla helps ensure that every component is fabricated and installed exactly as intended.

Revit for Integrated BIM Solutions

While Tekla excels in steel detailing, Revit provides us with the ability to create comprehensive Building Information Models (BIM) that integrate structural, architectural, and MEP elements into a single cohesive model. This multidisciplinary approach allows us to ensure that all building systems work harmoniously together, reducing the risk of clashes and ensuring a smoother construction process. With Revit, we can also collaborate with architects, engineers, and contractors in real-time, making it easier to coordinate efforts and resolve issues before they become problems on-site.

LEARN MORE – ADDITIONAL RESOURCES

Contact EcoSteel today to learn more about how our steel building solutions can benefit your next project.

𝗖𝗼𝗻𝗰𝗹𝘂𝘀𝗶𝗼𝗻: 𝗣𝗮𝗿𝘁𝗻𝗲𝗿𝗶𝗻𝗴 𝘄𝗶𝘁𝗵 𝗘𝗰𝗼𝗦𝘁𝗲𝗲𝗹 𝗳𝗼𝗿 𝗬𝗼𝘂𝗿 𝗡𝗲𝘅𝘁 𝗣𝗿𝗼𝗷𝗲𝗰𝘁

Structural 3D modeling is transforming the construction industry, offering greater precision, collaboration, and efficiency than ever before. At EcoSteel, we’re at the forefront of this innovation, using advanced tools like Tekla and Revit to deliver high-quality prefabricated steel buildings tailored to our clients’ needs. Whether you’re looking to build a commercial complex, a residential development, or an industrial facility, our expertise in 3D modeling ensures that your project is delivered on time, within budget, and to the highest standards of quality and sustainability.

WHY ECOSTEEL?

EcoSteel building systems come in a variety of shapes and sizes, but at their core they all utilize a custom engineered structural steel frame and a high-performance insulated shell. From sub-zero temperatures to dry heat or high humidity, Mother Nature continually tests the limits of building envelopes. While our insulated wall panels are a popular option, sometimes they are substituted or combined with masonry, stone, pre-cast or tilt-up concrete, wood, glass or other architectural wall treatments. The versatility and flexibility of our building systems allows for a myriad of colors, shapes, textures and designs. Today’s building projects require the perfect combination of energy efficiency, creative versatility, and reduced construction cost.

You must be logged in to post a comment.