Why Robotics Matters in PEMB Fabrication—The EcoSteel Approach

𝗜𝗻𝘁𝗿𝗼𝗱𝘂𝗰𝘁𝗶𝗼𝗻:

In today’s fast-paced world, where speed, accuracy, and sustainability are the keys to success in construction, robotics has stepped in as a true game-changer—particularly in the field of Pre-Engineered Metal Buildings (PEMB). At EcoSteel, we’re not just looking ahead; we’re actively shaping the future. By incorporating state-of-the-art robotic technologies into our fabrication processes, we’re transforming the way steel structures are designed, built, and delivered.

With tools like advanced laser cutters, CNC automation, robotic welding systems, and AI-driven quality control, EcoSteel is raising the bar for the industry. Our robotic fabrication not only boosts structural integrity and design flexibility but also cuts down on waste, labor inefficiencies, and production delays.

This article delves into the vital role that robotics play in PEMB fabrication and how EcoSteel harnesses this innovation to provide smarter, stronger, and faster building solutions.

1. Understanding Robotics in PEMB Fabrication

What are Pre-Engineered Metal Buildings?

Pre-Engineered Metal Buildings (PEMB) are structural systems that are designed and built off-site in controlled environments before being shipped out for assembly. They’re celebrated for their cost-effectiveness, quick construction times, and design flexibility, making them a popular choice for commercial, industrial, and institutional projects. These buildings are made up of precisely crafted steel components—like beams, columns, and roof panels—that fit together perfectly when they arrive at the site.

Defining Robotics and Automation in Modern Steel Fabrication

In the realm of steel fabrication, robotics refers to the use of programmable machines—such as robotic welders, CNC laser cutters, and automated material handlers—to carry out repetitive and precise tasks that were once done by hand. Automation enhances consistency, safety, and speed, especially when paired with software tools like CAD and BIM.

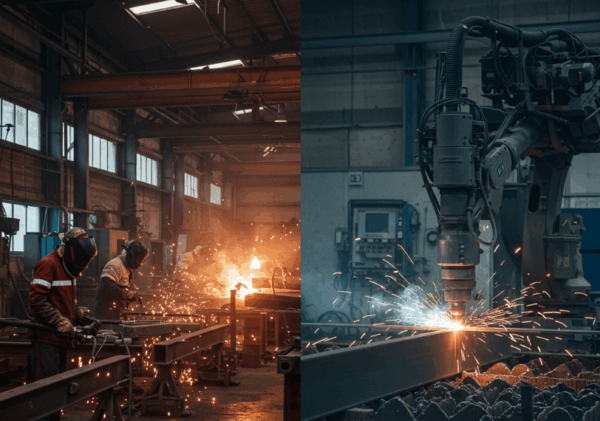

The Evolution from Manual to Automated Workflows in PEMB

Traditionally, the PEMB industry relied heavily on skilled labor, but it has seen a significant transformation. Today’s fabrication processes combine human skill with robotics, allowing companies like EcoSteel and other industry leaders to cut down on lead times, boost accuracy, and meet the growing demands of large-scale, high-performance construction.

2. Why Robotics Matter: Key Industry Challenges Solved

Reducing Human Error in Steel Processing

In the world of traditional steel fabrication, even the smallest mistakes in cutting, welding, or alignment can lead to expensive rework and structural issues. Robotics steps in to significantly reduce these risks by performing tasks with incredible accuracy and consistency. At EcoSteel, our robotic laser cutters and CNC systems guarantee that every steel component is crafted to match digital design specifications perfectly. This kind of precision not only boosts structural integrity but also makes the entire construction process smoother.

Tackling Labor Shortages and Rising Construction Costs

The construction industry is grappling with serious labor shortages and increasing wage demands. Robotics offers a scalable solution by automating repetitive, high-skill tasks without sacrificing quality. By incorporating robotic welding, cutting, and assembly systems, EcoSteel lessens its reliance on manual labor while ramping up production capacity, enabling us to complete more projects on time and within budget.

Meeting Tight Deadlines Without Compromising Quality

In today’s fast-paced construction landscape, time is of the essence. Robotics speeds up fabrication cycles by working continuously with minimal downtime. EcoSteel’s robotic systems allow for quicker throughput without compromising on quality, ensuring that buildings are completed faster while still upholding exceptional craftsmanship.

3. The EcoSteel Difference: Robotics at Work

At EcoSteel, robotics isn’t an add-on—it’s a foundational part of how we work. Our fabrication process begins with fiber laser cutting, which slices through steel with extreme accuracy and minimal waste. This ensures perfectly aligned components that reduce the need for field adjustments.

We also employ CNC-guided and robotic systems for creating insulated panel assemblies—managing cutting, insulation placement, and shaping with unmatched consistency. These thermally efficient panels arrive on-site ready for immediate installation. Our robotic welding and assembly systems create durable connections while reducing safety risks and manual labor exposure.

But our innovation doesn’t stop at the shop floor—it starts at the drawing board.

In an industry long driven by blueprints and rebar, a new chapter is unfolding—one where machines help conceptualize structures as much as they help fabricate them. At EcoSteel, this shift is not just theoretical—it’s operational. We begin many projects with a fusion of architectural intuition and AI-powered design tools, using machine-generated prompts to accelerate massing studies, structural layouts, and early-stage ideation. This doesn’t replace our architects or engineers—it enhances their creativity and speeds up the design process.

Once a concept is approved, our digital-to-fabrication workflow activates a tightly integrated network of robotic systems: laser cutters, CNC-controlled panel lines, and automated welders, all fed directly by our BIM/CAD models. The result is a seamless transformation of digital vision into real-world steel—with millimeter-level accuracy, reduced waste, and faster delivery timelines.

4. Benefits of Robotic Fabrication at EcoSteel

Robotics plays a pivotal role in EcoSteel’s fabrication process, delivering measurable benefits across every stage of Pre-Engineered Metal Building (PEMB) production. First, robotic systems ensure superior precision and structural performance by minimizing human error in cutting, welding, and assembly—resulting in components that fit perfectly and perform reliably under stress. Second, automation significantly accelerates project timelines, allowing steel elements to be fabricated, inspected, and delivered faster than with traditional methods. This speed is critical for clients working under tight construction schedules. Third, EcoSteel’s robotic tools optimize material usage through precise laser cutting and nesting, leading to reduced material waste and a more eco-friendly production cycle. Lastly, robotics create safer fabrication environments by taking over repetitive or hazardous tasks such as heavy lifting, plasma cutting, and welding—substantially minimizing workplace risk and ensuring compliance with strict safety standards. These combined benefits establish EcoSteel as a leader in efficient, sustainable, and safe PEMB delivery.

5. Real‑World Applications and Project Impact

One standout example illustrating how robotics streamlines PEMB fabrication comes from EcoSteel’s prefabricated manufacturing facility in Schiller Park, IL. Here, high-precision robotic systems—including fiber laser cutters, CNC panel lines, and robotic welders—were deployed across a 30,000-square-foot steel building project for EJ Basler. The integrated robotic setup enabled the seamless transition from BIM/CAD to automated fabrication, reducing build time by over 25%, while cutting dimensional errors to less than 1 mm. Material waste dropped by nearly 20%, thanks to optimized laser nesting and consistent robotic cuts. Overall, the client reported a 15% cost saving compared to traditional methods, driven by lower labor needs, faster cycle times, and minimal rework. The result? A high-performance facility delivered ahead of schedule with superior structural accuracy and energy efficiency—an emblematic case of how EcoSteel’s robotic approach directly benefits project timelines, budgets, and quality.

6. The Future of Robotics in PEMB: What’s Next for EcoSteel?

As technology advances at an exponential pace, EcoSteel is actively exploring the next frontier in robotic innovation—AI-enhanced design-to-fabrication pipelines. By integrating artificial intelligence with Building Information Modeling (BIM) and Computer-Aided Design (CAD) systems, we aim to create a fully automated workflow where machine learning algorithms optimize design configurations, material usage, and fabrication sequences in real time. This not only accelerates project delivery but also significantly reduces waste and cost. Looking further ahead, the potential for 3D robotic printing in steel construction is gaining traction. Although still in its early stages, this technology could eventually enable on-demand fabrication of complex steel components, reducing reliance on traditional assembly lines. At EcoSteel, our vision is grounded in a firm commitment to continuous innovation. We invest in R&D and strategic partnerships to ensure our fabrication process stays ahead of industry trends, pushing the boundaries of what’s possible in sustainable, high-performance metal building systems.

LEARN MORE – ADDITIONAL RESOURCES

Ready to future-proof your next building project? Contact EcoSteel today and experience the power of precision through robotics.

𝗦𝗵𝗮𝗽𝗶𝗻𝗴 𝘁𝗵𝗲 𝗙𝘂𝘁𝘂𝗿𝗲 𝗼𝗳 𝗦𝘁𝗲𝗲𝗹 𝗖𝗼𝗻𝘀𝘁𝗿𝘂𝗰𝘁𝗶𝗼𝗻 𝘄𝗶𝘁𝗵 𝗥𝗼𝗯𝗼𝘁𝗶𝗰𝘀

Robotic innovation isn’t just a cool tech trend—it’s essential for creating sustainable, high-performance metal buildings. As the world of architecture and engineering evolves, clients are looking for quicker delivery, more precision, and a smaller environmental footprint. Robotics steps up to meet these demands by automating key fabrication processes—from laser cutting and welding to insulation panel processing and quality control—making sure every component is crafted to exact specifications while minimizing waste. For EcoSteel, robotics isn’t just a passing fad; it’s a fundamental part of our strategy that boosts efficiency, safety, and scalability. By weaving intelligent automation into every step of our Pre-Engineered Metal Building (PEMB) workflow, we’re able to create smarter buildings that are not only stronger and greener but also ready to tackle the challenges of the future. As the industry embraces digital transformation, EcoSteel is at the forefront, merging design creativity with engineering accuracy.

WHY ECOSTEEL?

EcoSteel building systems come in a variety of shapes and sizes, but at their core they all utilize a custom engineered structural steel frame and a high-performance insulated shell. From sub-zero temperatures to dry heat or high humidity, Mother Nature continually tests the limits of building envelopes. While our insulated wall panels are a popular option, sometimes they are substituted or combined with masonry, stone, pre-cast or tilt-up concrete, wood, glass or other architectural wall treatments. The versatility and flexibility of our building systems allows for a myriad of colors, shapes, textures and designs. Today’s building projects require the perfect combination of energy efficiency, creative versatility, and reduced construction cost.