Our Complete Building Process

EcoSteel is committed to an active involvement from the earliest stages of a project, aiming to develop a supportive relationship with our client and their professional team. Assistance is provided with both, technical and budget issues and carefully considered value engineering, the development of connection details and innovative erection schemes frequently providing benefits to the construction program and the scheme budget.

Our prefab sequence is simple

At EcoSteel we simplify the build process into what we call the Prefab Sequence. Our team will work with you through the Prefab Sequence from our initial accessibility review, and we have designs that are Pre-Engineered for both the MicroHome and foundation specific to your site. We have a Slab option for flat sites and a steel/ raised floor option for sloped sites to have unlimited access for your new MicroHome.

For a complete breakdown of each of the Prefab Sequence steps, please click on each topic to expand.

STEP ONE – SECURE THE LAND

The first step to getting started with EcoSteel is to secure the land which you are looking to build on. It is important to have the project site selected first so that you can design your building to fit the parameters of the site. EcoSteel is committed to an active involvement from the earliest stages of a project, aiming to develop a supportive relationship with our client and their professional team.

STEP TWO – ESTABLISH CONSTRUCTION BUDGETS

Assistance is provided with both, technical and budget issues and carefully considered value engineering, the development of connection details and innovative erection schemes frequently providing benefits to the construction program and the scheme budget. The next step to building with EcoSteel is to discuss design requirements and target completion budgets. It is very import to know the target completion budget up front so that EcoSteel can reverse engineer your building design to maximize the building features you value most.

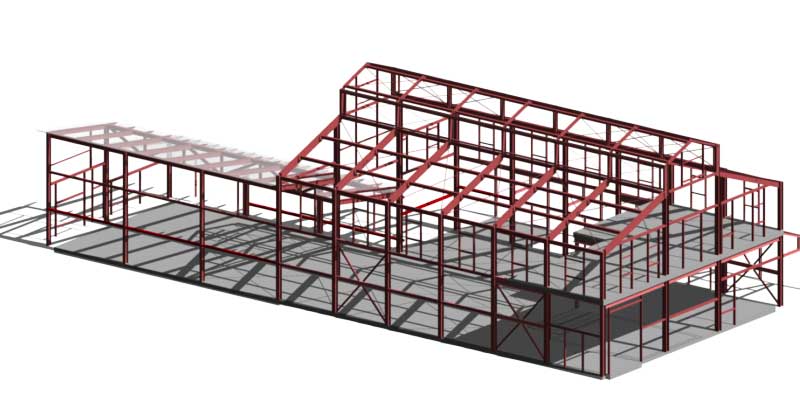

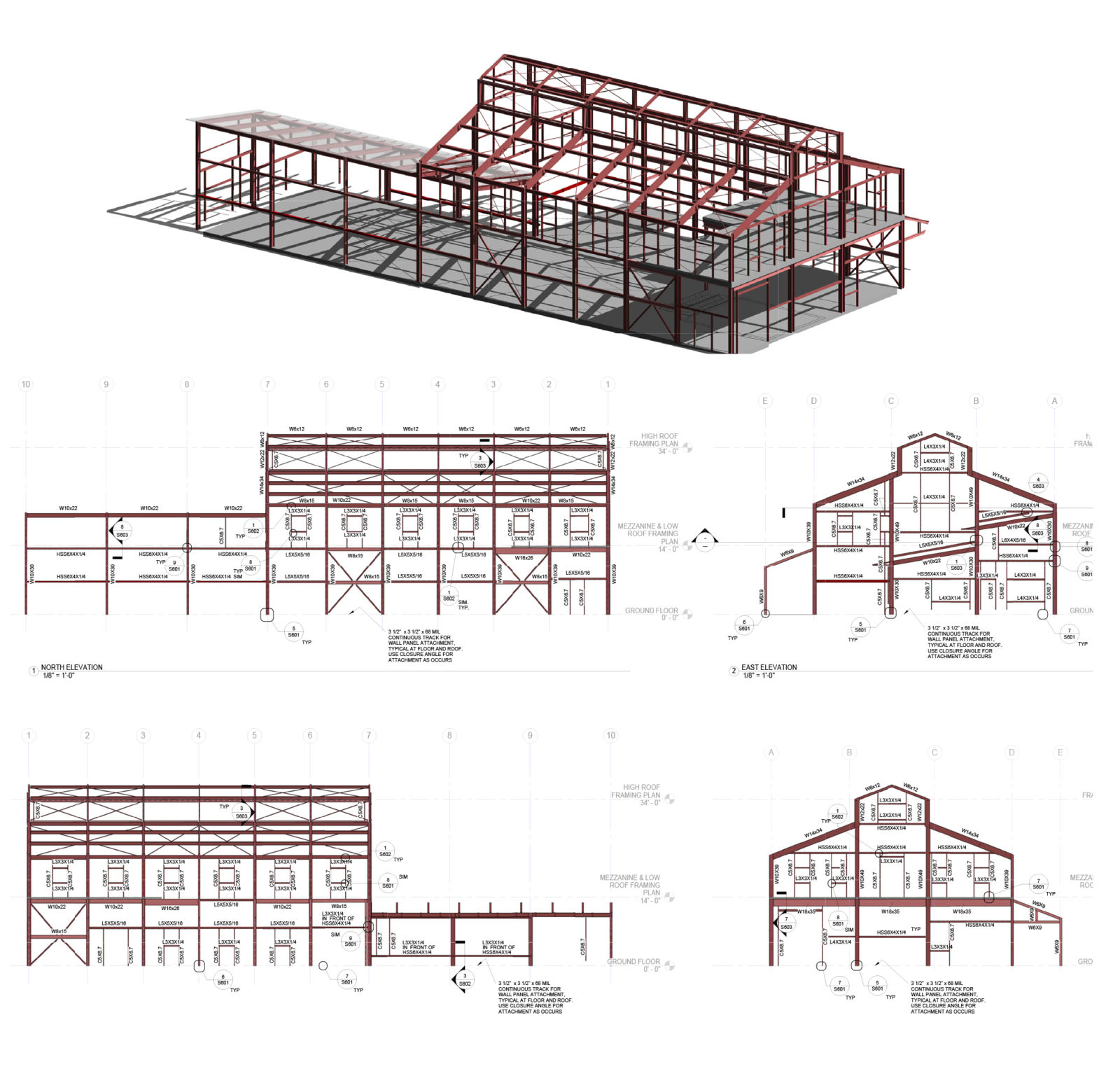

STEP THREE – VALUE DRIVEN 3D STEEL DESIGN

Now that budgets have been established, we convert your rough sketches or architectural designed plans into a robust pre-engineered EcoSteel construction system. Our team creates a 3d model to analyze the structure for potential conflicts while maintaining the visual aesthetics of the project. We’ll model your entire building system to translate the schematic design into a steel construction system with a panelized exterior skin. Material transitions, panel alignment and basic waterproofing solutions are provided to confirm the design integrity is maintained.

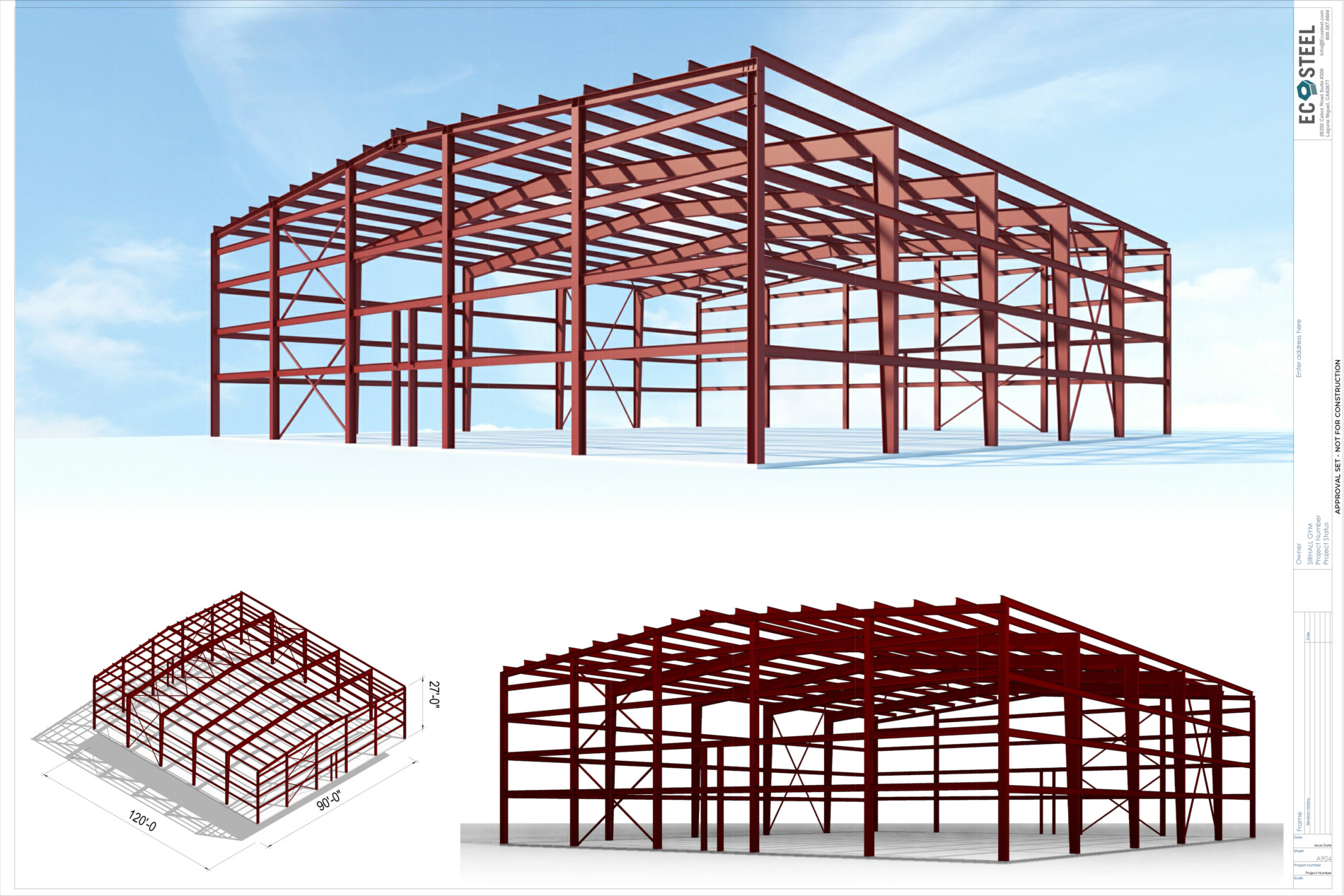

STEP FOUR – PRE-ENGINEERING PERMIT BLUEPRINTS

Once Ecosteel and your Architect have agreed on a final design and framing layout, we finalize our structural drawings. EcoSteel designs exclusively with pre-engineered steel building components. Our buildings are designed to meet or exceed local code. We provide the the structural engineering stamp needed for permit along with a few high resolution exterior renderings to assist with city design approval.

STEP FIVE. State-required Permit Submittal

Once all architectural, engineering and certification documentation is complete, all drawings and accompanying documentation are compiled and can be submitted for Building Permits to your local building Officials for review and approval. This is done by the client or GC.

STEP SIX – SOFTWARE DRIVEN FABRICATION

Ecosteel 3d framing model is inputed into a material list on a factory computer. The factory computer then runs the machinery that fabricates the steel in an assembly line style. All parts and pieces are labeled and numbered during this fabrication in the factory. All insulated roof and wall panels are pre-finished with standard or custom colors in the factory prior to install.

STEP SEVEN – ECONOMICAL DELIVERY

EcoSteel has 13 shipping points nationwide. All steel materials are flat packed for economical transportation. Smaller flat bed truck shipping is available for project sites with difficult access. All parts and pieces will need to be inventoried by your build team. At this time, your contractor will have your foundation completed so that your erector can start steel assembly after a full inventory has been made.

STEP EIGHT – RAPID STEEL ASSEMBLY

EcoSteel systems require an experienced contractor to build efficiently. All steel material parts are pre-cut, pre-drilled, and bolted for rapid assembly that any certified steel erector can assemble with ease. Unlike wood structures (and wood is a traditional construction material), steel structures do not take months, or years, to erect. Since steel arrives at the construction site pre-fabricated and pre-engineered, the process of erecting your custom designed steel building is a quick job for an experienced contractor. Our factory finished insulated roof and wall panel system will enclose you building shell eliminating multiple sub-contractors.

STEP NINE – CONTRACTOR FINISHING

Once your EcoSteel system is installed, your other subcontractors will have a safe and ready shell to finish your building. All steel members are trHigh Performance Steel Buildings – California Luxury Residential – Fire Resistant – Fast Construction – Title 24 – Energy Efficient – Commercial Constructionade ready to speed up the installation of your MEP systems. Leave your steel completely exposed for a minimalist look or partially finish it with drywall for a more traditional warm interior feeling. Either way, your home or business will be safer using our steel system.

STEP TEN – MOVE IN!

Now that you building has been complete it’s time to celebrate. You now have a high performance building that is fire, mold, and termite resistance. The versatility and flexibility of our building systems allows for a myriad of colors, shapes, textures and designs. Today’s building projects require the perfect combination of energy efficiency, creative versatility, and reduced construction cost. Your energy costs will be cut significantly and you building maintenance should be minimal.