SUSTAINABILITY & LEED CREDITS

EcoSteel is committed to the future and the environment.

Our Commitment

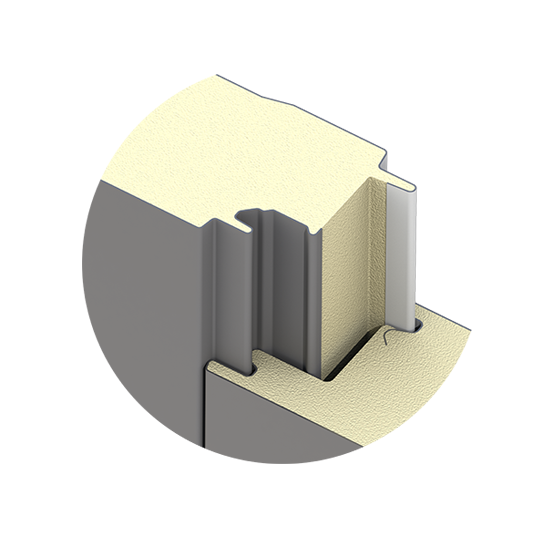

Our insulated metal panels are manufactured to deliver superior thermal capabilities designed to minimize the use of energy required in the heating and cooling of buildings. We manufacture using materials that meet or exceed regulatory standards for the reduction of global warming potential and our panels have zero ozone depleting potential. We also use recyclable materials to produce 100% recyclable products and incorporate finishes that are engineered to reduce the carbon footprint and maximize solar reflectance and thermal emissivity.

This page will help architects, specifiers, and design professionals identify the sustainability benefits, attributes and performance criteria of insulated metal panels relative to qualifying for credits within the U.S. Green Building Council’s Leadership in Energy and Environmental Design (LEED) Green Building Rating System.

“ECOSTEEL IS COMMITTED TO THE FUTURE AND THE ENVIRONMENT.”

LEED CREDITS

LEED SS Credit 7.2 – Heat Island Effect – Roof

Roofing products used on at least 75% of the roof will qualify for this credit when the Solar Reflectance Index (SRI) is at least 78 for low-sloped roofs and 29 for steep sloped roofs. All standard colors qualify for steep-sloped applications while Regal White and Imperial White qualify for low-sloped applications. These values may be found at the color table on the second page.

LEED EA Prerequisite 2 – Minimum Energy Performance

EcoSteel Panels contributes to higher energy efficiency and complies with the requirements of ANSI/ASHRAE/IESNA Standard 90.1-2007.

LEED EA Credit 1 – Optimize Energy Performance

The purpose of this credit is to increase levels of energy performance in comparison to mandatory standards. EcoSteel Panels have been tested for thermal transmittance using ASTM C518: Steady State Thermal Transmission and ASTM C1363: Hot Box Apparatus. Using insulated panels can contribute to points for the whole building design and demonstrate a performance rating that exceeds the baseline performance rating of ANSI/ASHRAE/IESNA Standard 90.1-2007.

LEED MR Credit 1.1, 1.2 and 1.3 – Building Reuse

EcoSteel Panels used in an existing building can be disassembled and reused for both the building envelope and the interior of a new project.

LEED MR Credit 3 – Materials Reuse

EcoSteel Panels can be reused and contribute to the points for using salvaged, refurbished or reused materials for 5% of all project materials.

LEED MR Credit 4.1 and 4.2 – Recycled Content

Steel facings on EcoSteel Panels contain a total recycled content of up to 30%. This includes the total percentage of post-consumer recycled content as well as ½ pre-consumer recycled content.

LEED IEQ Credit 4.1 – Low-Emitting Materials – Adhesives and Sealants

Sealants used in EcoSteel Panels comply with the South Coast Air Quality Management District Rule #1168 and have Volatile Organic Compounds (VOCs) below the maximum limit of 250 grams/liter.

LEED IEQ Credit 8.1 – Daylight and Views – Daylight

Integration of EcoSteel Panels skylights and wall lites can help reduce the use of electric lighting in occupied areas.

LEED WE Credits 1-3 Water Efficient Landscaping, Innovative Wastewater Technologies, Water Use Reduction

EcoSteel roofing systems can be integrated into the building’s rainwater harvesting system and contribute to reduced potable water consumption, building sewage conveyance and a 20% reduction of the baseline water usage calculated for the building.

LEED ID Credit 1 – Innovation in Design

Buildings designed with EcoSteel Panels have the potential to provide exemplary performance and to exceed the requirements set forth by the LEED Rating System.

Global Stewardship

Volatile Organic Compound (VOC)

EcoSteel Panels do not contain VOCs and do not contribute to air pollution.

Ozone Depleting Potential (ODP)

EcoSteel Panels have zero Ozone Depleting Potential and there are no limits by the EPA or Environment Canada for its use today or in the future.

Global Warming Potential (GWP)

EcoSteel Panels meet EPA blowing agent requirements for the reduction of Global Warming Potential.

R-VALUES OF OUR PANELS

R-Values for 75º mean based on ASTM C518: Steady State Thermal Transmission. R-values for 40º mean based on interpolated data from ASTM C1363: Hot Box Apparatus. Values shown are for general use only. They do not reflect system or specific end-use insulation values.

| Thickness | 75º Mean | 40º Mean | |

| 2’’ | 15.72 | 16.95 | |

| 2.5’’ | 19.45 | 21.19 | |

| 3’’ | 23.18 | 25.42 | |

| 3.25’’ | 25.05 | 27.54 | |

| 4’’ | 30.65 | 33.89 | |

| 5’’ | 38.12 | 42.36 | |

| 6’’ | 45.59 | 50.84 |

Exterior Reflectivity and Emissivity Values

| Solar Reflectance Index | Emissivity | Initial Reflectance | |

| PVDF In-stock Colors | |||

| Sandstone | 69 | .83 | .59 |

| Surrey Beige | 56 | .84 | .50 |

| Regal White | 86 | .84 | .71 |

| Royal Blue | 29 | .85 | .29 |

| Natural Green | 32 | .85 | .32 |

| Pearl Gray | 56 | .83 | .50 |

| PVDF Non-stock Colors | |||

| Warm White | 78 | .85 | .65 |

| Slate Gray | 39 | .84 | .37 |

| Evergreen | 30 | .85 | .30 |

| Slate Blue | 47 | .85 | .43 |

| Colonial Red | 33 | .83 | .33 |

| Weathered Copper | 31 | .84 | .31 |

| SMP In-stock Colors | |||

| Imperial White | 83 | .85 | .69 |

| Sandstone | 66 | .87 | .56 |

| Surrey Beige | 48 | .87 | .43 |

ENERGY STAR ® Requirements:

Initial Reflectance – Minimum value of 0.65 for Low-Sloped Roofs (Less than or equal to 2:12)

Minimum value of 0.25 for Steep-Slope Roofs (Greater than 2:12)

LEED-NC Requirements:

Solar Reflectance Index – Minimum value of 78 for Low-Sloped Roofs (Less than or equal to 2:12)

Minimum value of 29 for Steep-Slope Roofs (Greater than 2:12)

INSPIRATION GALLERY